Shoes

- Out-Of-Office Sale

- Shop All

- Sandals

- Loafers & Mules

- Flats & Slip Ons

- Sneakers

- Heels

- Boots

- Baby, Toddler & Kids Shoes

- Sale

Out-Of-Office Sale

Shop All

Sandals

Loafers & Mules

Flats & Slip Ons

Sneakers

Heels

Boots

Baby, Toddler & Kids Shoes

Sale

Accessories

Bags + Wallets

Belts

Socks

Collections

Best Sellers

New Arrivals

Work Wear

Sale

Sustainability

- Our Sustainability Framework

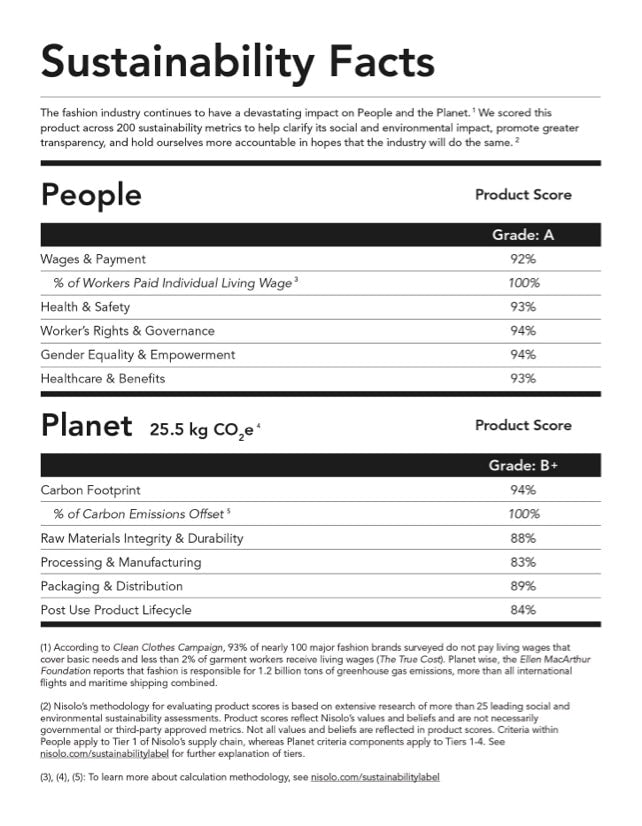

- Sustainability Facts Label

- 100% Living Wages

- 0% Net Carbon

- Certified B Corporation

- Donate Your Old Shoes

Our Sustainability Framework

Sustainability Facts Label

100% Living Wages

0% Net Carbon

Certified B Corporation

Donate Your Old Shoes

Connect

Our Stores

Returns/Exchanges

FAQs

Careers

Corporate Gifting

Accessibility Statement

Shoes

- Out-Of-Office Sale

- Shop All

- Sandals + Slip Ons

- Sneakers

- Boots + Chukkas

- Oxfords + Loafers

- Styles Under $150

- Sale

Out-Of-Office Sale

Shop All

Sandals + Slip Ons

Sneakers

Boots + Chukkas

Oxfords + Loafers

Styles Under $150

Sale

Sale

Accessories

Shop All

Bags + Wallets

Belts

Socks

Collections

Best Sellers

New Arrivals

Work Wear

Essentials

Sustainability

- Our Sustainability Framework

- Sustainability Facts Label

- 100% Living Wages

- 0% Net Carbon

- Donate Your Old Shoes

Our Sustainability Framework

Sustainability Facts Label

100% Living Wages

0% Net Carbon

Donate Your Old Shoes

Connect

Our Stores

Returns/Exchanges

FAQs

Careers

Corporate Gifting

Accessibility Statement

Live Chat