As we shared on this page, the fashion industry is a mess and continues to have a detrimental impact on People and the Planet. We believe a comprehensive and holistic approach to sustainability evaluation that leverages tools which empower consumers to make better choices and enable brands to improve their practices is key to rewriting the way Fashion operates.

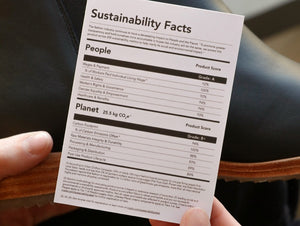

We introduced the Sustainability Facts Label for this purpose, and our hope is that the Breadth, Depth, and Digestibility of our label become the floor for future labels to be built upon.

An agreed-upon, comprehensive methodology for rating a product’s impact on People and the Planet that’s ALSO digestible to consumers does not exist. This is problematic because it perpetuates social and environmental injustices prevalent in the fashion industry.

Hundreds of millions of people (the vast majority of whom are young women) are held in poverty everyday because the fashion industry fails to pay its workers a living wage (Source: Clean Clothes Campaign, 2020). The consequences of lacking an established framework for measuring our products’ impacts are also dire for the planet, which is undergoing accelerating climate change at the hands of the fashion industry as well. Fashion is responsible for 1.2 billion tons of annual greenhouse gas emissions, more than all international flights and maritime shipping combined (Source: Ellen Macarthur Foundation, 2017). The People who are held in poverty at the hands of the fashion industry cannot wait any longer and neither can our Planet, whose climate will be irreparable if we do not course correct as a society soon.

Our Sustainability Facts Label Methodology

Why we’re launching this Label now

We started Nisolo because of the lack of integrity across People and Planet within supply chains. We’ve been focused on social and environmental responsibility from day 1 because we believe the fashion industry has the potential to significantly reduce global poverty and reverse its impact on climate change within our lifetime. We’ve spent over 10 years in this work—making tons of mistakes and experiencing wins as well—learning our way into what a comprehensive approach to sustainability actually needs to look like. We’ve been encouraged over the last half decade to see all of the momentum in the sustainability movement. However, it has been challenging and discouraging for us to watch the emergence of ongoing broad sustainability claims in the industry without the practices to back them up. Too many brands spend more time, effort, and money on appearing to be socially and environmentally responsible than actually investing in ways to be more responsible.

We all know that without transparency, there can be no accountability. Without accountability, there can be no change. Said in another way, without greater transparency, the fashion industry can’t change.

So, starting four years ago, we began surveying the industry for helpful tools and labels, knowing that a critical component of a successful sustainability movement would be restoring trust between consumers and brands. We began to realize that one of the biggest threats to the sustainability movement is greenwashing and confusion among consumers. What does sustainability mean and what does it not mean? What should we care about from a People and Planet perspective?

We realized that a tool was needed that was digestible and comprehensive for consumers, and when we surveyed the market we couldn’t find one. While we never imagined creating our own and in many ways wish we were not a brand behind this label because of the biased perception of this tool when made by a brand, we decided that People and Planet were far too important, and the issues we’re facing far too urgent, to stand on the sidelines and wait. We remain underwhelmed by what is in the market from a labeling perspective, and those that seem most promising are still on far too long of timelines to be introduced to market when considering the urgency and importance of issues facing People and Planet.

For far too long, we as consumers have been left out of the conversation of the role we play in fixing fashion. And yet, we as consumers are the ones who enable the industry to operate the way it does. We launched the Sustainability Facts Label to equip consumers with the necessary information to shop responsibly and ultimately shift the industry in a more sustainable direction.

Doing this required us to develop a methodology that assesses our products’ social and environmental impacts. A rating is only as legitimate as the methodology behind it, which is why our team, with decades of cumulative experience in the fashion industry, has spent hundreds of hours researching existing social and environmental standards, assessments, labels, and ratings criteria to inform a methodology we have confidence in.

That said, we're by no means experts, and in some ways, the humility that goes along with that self recognition is one of the reasons we believe we were able to effectively and efficiently come up with comprehensive criteria worthy of being built upon. What we mean by that is that in developing these criteria, unlike a lot of other assessment tools, from the start, we did not have a horse in the race, which is what allowed us to objectively aggregate criteria across so many organizations and efficiently determine where commonalities existed. This enabled us to ensure relatively quickly that what experts commonly deem most critical made its way into our methodology.

Before going any further, we want to give a special thanks to everyone listed in our Bibliography of resources at the very bottom of this post as well as a special thanks to the industry standards, assessments, tools, ratings, and consumer facing labels that helped inform our methodology. They include but are not necessarily limited to the following:

- Sustainable Apparel Coalition’s Higg Index

- Better Work Programme resources from the International Labour Organization and International Finance Corporation

- Social Accountability International’s SA8000 Standard

- Fair Labor Association’s Workplace Code of Conduct and Compliance Benchmarks

- Fair Trade USA’s Factory Standard for Apparel and Home Goods

- B Lab’s B Impact Assessment

- Global Living Wage Coalition’s Family Living Wage Methodology and Benchmarks

- Wage Indicator and Trading Economics’ Individual Living Wage Methodologies and Benchmarks

- Eco-Age’s Sustainability Benchmark

- Accountable’s Factory Auditing Assessment

- Textile Exchange’s Organic Content Standard

- Cradle to Cradle’s Product Standard

- Climate Neutral’s Standards

- Doconomy’s 2030 Calculator for CO2 Emissions

- Eon’s Digital ID

- Accenture’s Impact Index

- Leather Working Group’s Audit Protocols

- Framework for Regenerative Organic Certified Products

- ZQ’s Grower Standard Manual

- Savory Institute’s Land to Market Program

- Oeko-Tex’s Standard 100

- bluesign’s CRITERIA for production sites

- REACH Criteria and Guidelines

- Re/Make’s Fashion Accountability Report Methodology

- Good On You’s Ratings Guide

- Fashion Revolution’s Fashion Transparency Index Methodology

- Asket’s Impact Receipt

- Allbirds’ Carbon Footprint Label

- Cocokinds’ Sustainability Facts Label

- Pantys’ Carbon Footprint Label

- Invisible Bag’s Packaging Label

In this post, we present the body of research we reviewed to build our ten-category methodology in addition to context around how the fashion industry is currently performing through those ten categories. We share the ins and outs of how our methodology works, the social and environmental criteria each category assesses, and how we evaluated our products.

We want to be clear up front that this scoring methodology is not perfect. We will be the first ones to name that. However, we believe this is urgent to get out into the world for all of the obvious reasons impacting People and Planet today, but also because of the tragic lack of assessments and product labels in existence that represent the Breadth, Depth, and Digestibility required to actually course-correct the fashion industry. More and more consumer facing labels are getting released, but most only assess one or two metrics and are not embracing a holistic approach to sustainability. Conversely, holistic assessments and standards are still years away from getting a label on apparel and footwear that actually mobilizes consumers to take action now on prevailing social and environmental injustices in Fashion.

Our intention with this label and methodology is to raise the floor for transparency. Similar to the food industry, the fashion industry needs a comprehensive product label that rates products holistically. Accountability is needed to drive industry-wide change, which is why we’re calling on industry experts to urgently build this out further and hold brands, ourselves included, accountable for our impacts on People and the Planet. We welcome all constructive criticism, and we recognize that real impactful change at scale for the betterment of People and the Planet must happen in collaboration.

As a Certified B Corporation, Climate Neutral Certified brand, and member of the Leather Working Group, we believe in the essential role that 3rd party certifications, independent organizations, and standards play in driving socially and environmentally responsible business practices.

The strength of what we’re bringing to the table with this label is the result of collecting a wide breadth of research, rigorously evaluating it, and then boiling it down into one, simple, digestible label for consumers—something that has never been done before in such a comprehensive yet simplified manner.

For the People categories, the assessment of our own products only evaluates Tier 1 suppliers where products are made into finished goods. However, we built our framework and methodology for the People categories in a way that can be applied to all four tiers of a brand’s supply chain, such as: Tier 1–finished goods factories, Tier 2–dimensions like leather tanneries, Tier 3–suppliers such as hide processors, and Tier 4-the origin of raw materials such as the farm level.

Whereas our Planet section of the label is already inclusive of each tier of the supply chain (in addition to all three scopes of carbon emissions that are emitted directly or indirectly via production and distribution), as a small, under-resourced brand, thus far we’ve only been able to rigorously evaluate and build into the evaluation of our own products for People, our Tier 1 suppliers (though we pledge to add more tiers over time).

Who informed our People criteria and grading scale?

At the heart of the People criteria we assess are components from Sustainable Apparel Coalition’s Higg Index, Social Accountability International’s SA8000 Standard, Fair Labor Association’s Workplace Code of Conduct and Compliance Benchmarks, Better Work Programme resources from the International Labour Organization (ILO) and International Finance Corporation (IFC), Fair Trade USA’s Factory Standard for Apparel and Home Goods, B Lab’s B Impact Assessment, Global Living Wage Coalition’s family living wage methodology and benchmarks in Peru, Mexico, and Kenya, Wage Indicator and Trading Economics’ individual living wage methodologies and benchmarks in Peru, Mexico, and Kenya, Eco-Age’s Sustainability Benchmark, and Accountable’s Factory Auditing Assessment.

These standards, assessments, and tools are helping lead the way in establishing the framework and systems for factories to adopt in order to cultivate an environment where workers thrive through laying out best practices for social responsibility.

Who informed our Planet criteria and grading scale?

At the heart of the Planet criteria we assess are components from Sustainable Apparel Coalition’s Higg Index (once again), Textile Exchange’s Organic Content Standard, Cradle to Cradle’s Product Standard, B Lab’s B Impact Assessment, Climate Neutral’s Standards, Doconomy’s 2030 Calculator for CO2 emissions, Eon’s Digital ID, Accenture’s Impact Index, Leather Working Group’s Protocol, Framework for Regenerative Organic Certified Products, ZQ’s Grower Standard Manual, Savory Institute’s Land to Market Program, Oeko-Tex’s Standard 100, bluesign CRITERIA for Production Sites, REACH Criteria, and Eco-Age’s Sustainability Benchmark.

These standards, assessments, and tools are helping lead the way in establishing best practices for environmental responsibility at every tier of Fashion’s supply chain.

Inevitably, we had to make some tradeoffs between Breadth, Depth, and Digestibility in order to make our methodology criteria both relevant for everyday consumers and comprehensive and actionable for any brand across various fashion product categories (apparel, footwear accessories, etc.) to adopt. The beauty of this methodology and label is that it can be applied to any product. It is not specific to leather footwear and accessories, a cotton t-shirt, wool sweater, denim jeans, linen shirt, etc., Rather, any product or category can be assessed and graded using the same 200 criteria we put into our methodology. In fact, the ten categories assessed under People and Planet could be applied to any industry. Imagine a world where you knew the social and environmental impacts of everything prior to purchasing! Oh, what a world that would be.

Whereas we have included all major topics across People and Planet that the organizations listed above typically evaluate, we did not include 100% of the criteria from certifications or assessments that are focused on one specific raw material. For example, we did not include such specific line items as shearing practices and guidelines for wool production (which some wool certifications cover) given this is so specific to that raw material. However, anytime an industry standard or assessment was focused on one specific material or impact, we made sure to include it in a broader criteria line item. Using the same example of wool to exemplify what is meant by that, whereas we did not get as granular as exact shearing methodology, we did include the broader criteria of having a commitment to and ensuring the 5 freedoms of animal welfare, which can be seen in category 2–Raw Materials Integrity and Durability–under Planet. Additionally, we reward products that have met specific 3rd party certifications (like the Responsible Wool Standard) in the 95-100 scoring section across each of their ten categories so as to recognize the depth of impact such certifications carry.

Although there are a lot of standards and a growing number of independent brand labels in existence, we believe there’s more the fashion industry should be assessing and publicly sharing and that when approaches are not comprehensive and digestible, often times more harm than good can be done.

Industry standards are typically hyperfocused on one particular issue or too broad in their assessment of several. Similarly, most independent brand labels only report on one or two key metrics when a product’s overall impact is much more complex. For that reason, we’ve compiled the comprehensive work of industry experts into a product level evaluation with 200 data points of criteria (92 in People; 108 in Planet) that we deem critical to measure and share with consumers. We’ve also included criteria that’s not as prevalent in assessments and standards (e.g., public transparency of lowest wages, women empowerment programming, supplementary benefits, etc.) across all ten of our methodology categories where we felt like existing assessments were still missing the mark.

In summary, we’ve assessed the fashion industry, drawn together the best standards and assessments, included criteria we believe the industry should account for, and made everything digestible in order to activate consumers to actually drive change through demand in our industry.

With this context in mind, let’s dive into the ins and outs of our methodology, beginning with how our grading scale works, in addition to how we calculate living wages, our products’ carbon emissions, and carbon offsets.

How our grading scale works:

Scores range from 0 to 100 with higher scores reflecting better practices. Each category has non-negotiables, meaning that if any of the criteria for a 0 score is true–for example, if child labor exists in the supply chain–the product rates as a 0 even if it meets other criteria in that category. We created 10 point ranges instead of a weighted algorithm that calculates a specific percentage score because we want to get feedback on how to improve our methodology before getting hyper-particular on how a product should be assessed. A 50-59 rating is still a failing score because this implies that only the bare minimum is being done, which is actually how much of the industry is performing. For a product to qualify for the next 10-point range, it must meet all of the criteria in the previous range because each 10-point range is meant to build upon what precedes it.

To calculate exact percentages, we took the total number of line items within a range applicable to the product, divided that number by the total number of line items in the range, and then multiplied that by the total number of points achievable within the range. For example, if a product qualifies for 4 out of 5 criteria in the 80-89 range of Processing & Manufacturing, ⅘=.8; 10 points in the range x .8 = 8 total points achieved in that section, which results in 87% since 80% is included as one of the percentage points. We’ve structured the top tiers, 90-94 and 95-100, to be difficult to attain. These line items represent exemplary and best in class practices backed by 3rd party certifications. Our hope is that these higher ratings help brands and suppliers create a roadmap for improving their products and supply chains. To calculate letter grades, we took the average of all six line items under People and Planet, inclusive of the percentage of workers receiving an individual living wage and percentage of carbon emissions offset.

How we calculate living wages:

A living wage is sufficient to cover a decent standard of living inclusive of food, water, housing, education, healthcare, transportation, clothing, and other essential needs with some discretionary income to spare. We calculate individual living wages in the countries we source from using 3rd party wage research from Wage Indicator and Trading Economics. We calculate family living wages with benchmarks from the Global Living Wage Coalition. You can learn more about wages within our supply chain here.

How we calculate our products’ carbon emissions:

We assess our product’s carbon emissions using raw materials weight data collected from our Tier 1 suppliers that we inputted into the 2030 Calculator by Doconomy, a technology platform powered by emissions data from Ecoinvent, “the world’s most consistent and transparent life cycle inventory database supporting environmental assessments of products and processes worldwide.” The European Commission has chosen Ecoinvent as the one supplier for emissions data when future legislation on product carbon footprint limitations come into play.

The scope of our product emissions LCA are cradle to gate, which means they include CO2 emissions from materials, manufacturing, and transportation from suppliers to our distribution center in Nashville, Tennessee. This LCA is not inclusive of CO2 emissions generated by transportation to the customer, packaging, product use, or end of life. Doconomy’s reason for using cradle to gate instead of a cradle to grave or cradle to cradle scope is so that the LCA calculation is based on data and not estimated. In order to include the last mile, product use and end of life, we would need to provide our own estimates, which would not be backed by reliable data. Additionally, this LCA does not take into account our product’s impacts on water, eutrophication, land occupation, and other natural resources. It only evaluates CO2 emissions.

While this is by no means a 100% perfect LCA–we are reliant on the accuracy of weights provided to us by suppliers, Ecoinvent’s emissions database, and Doconomy’s platform–we are confident that these emissions values are sufficiently accurate so as not to mislead consumers. As a Climate Neutral Certified brand, we are measuring, reducing, and offsetting 100% of our carbon emissions through Verified Carbon Standard Certified carbon credits in the Peruvian Amazon that may fund projects occurring in the future, and believe that public transparency of our product’s carbon footprint is a step in the right direction towards solving the climate crisis. Whereas the estimate of CO2 emissions per product comes from Doconomy, we actually offset more than that per Climate Neutral’s approach, which is inclusive of all business activities.

How we calculate our carbon offsets:

As a Climate Neutral Certified brand, we have measured and offset 100% of our Scopes 1, 2, and 3 CO2 emissions for everything we produced in 2019 and 2020 according to Climate Neutral’s methodology. We will measure and offset 100% of our CO2 emissions for 2021 in April 2022. For a quick overview of what is covered in each Scope:

- Scope 1 are direct emissions that come from controlled facilities, such as the factory we own and operate in Peru and our corporate facilities in Nashville, Tennessee. These include the fuel we consume in company vehicles, the natural gas we use to heat our facilities, and direct emissions from our factory in Peru.

- Scope 2 are indirect emissions, which account for CO2 emissions created by purchased electricity.

- Scope 3, and the most significant, are indirect emissions from our supply chain, which is inclusive of emissions released from extracting raw materials used for finished products, corporate business travel, employee commuting, and upstream and downstream shipping.

Climate Neutral ensures that we are accurately measuring and offsetting 100% of these emissions by requiring us to measure our emissions on their software tool, the Brand Emissions Estimator (BEE), a comprehensive platform built in partnership with climate experts from well respected organizations–Massachusetts Institute of Technology and CIRAIG, among others–operating in the carbon emissions accounting and lifecycle analysis fields (see their complete methodology here). To certify, we share financial information and specific emissions data (e.g., total ton miles shipped, kilowatts of energy consumed, therms of natural gas used, amount of leather hides purchased, etc.) into the BEE to arrive at an accurate estimate of our total carbon emissions. An analyst from Climate Neutral works directly with our Sustainability Lead to ensure there are no discrepancies in the data, supports us with creating and implementing reduction plans to actually reduce our carbon footprint moving forward, and verifies that 100% of our CO2 emissions are offset annually through a REDD+ project in the Peruvian Amazon that has been certified through the Verified Carbon Standard (VCS). You can learn more about the conservation work we support here and here.

Now, let’s unpack the core 10 criteria we assess across People and Planet by exploring the state of the fashion industry, in addition to how we evaluate our products.

People

We envision the fashion industry becoming a vehicle for eradicating poverty for hundreds of millions of the world’s most vulnerable people, and inspiring other industries to pull their stakeholders out of poverty as well. Realizing this vision requires that we create and cultivate work environments where workers can thrive. To us, this means paying living wages, providing a healthy and safe workplace, elevating worker’s rights through ensuring ethical governance, empowering women, and offering healthcare and benefits. We’ve structured our scoring criteria around these five categories.

Wages & Payment

State of the fashion industry

Did you know that 93% of fashion brands are not paying factory workers a living wage that covers their basic needs (food, water, shelter, healthcare, etc.) (Source: Clean Clothes Campaign, 2020)? Experts estimate that less than 5% of people making clothing around the world receive a living wage, meaning 95% of producers in the fashion industry are being held in systemic poverty. And, 75% of them are women between the ages of 18 and 24 (Source: Fashion Revolution, 2017).

This is not a small problem. In fact, the fashion industry employs 75 Million factory workers around the world (that’s a higher number than the population of over 220 different countries) (Source: Fashion United, 2017). Factoring in that many workers have children, the number of people this problem affects quickly becomes as large as the population of the United States, the 3rd largest country in the world.

Our industry’s negligence to provide a living wage is especially concerning when considering that the United Nations has declared it a basic human right.

“Everyone who works has the right to just and favorable remuneration ensuring for himself and his family an existence worthy of human dignity...”

(Source: Universal Declaration of Human Rights, Article 23.)

Even if brands provide the legal minimum wage, that wage is less than half of what's considered a living wage in most Asian countries where the majority of the world’s clothes are made (Source: Clean Clothes Campaign, 2013). Unfortunately, all of this means that the products you enjoy most–your favorite pair of jeans, your go-to pair of shoes, that first outfit worn when the laundry is done–were likely made by people who are unable to meet the basic needs of themselves and their children. This is especially troubling in light of the fact that “if brands absorbed this entire cost of paying living wages within their supply chains, for mere pennies per product, it would cost them, individually, less than 1 percent of the price of a garment–that’s 17 cents on a $25 shirt.” (Source: Bédat, 2021)

One of the root issues for why workers do not receive a living wage is that brands “race to the bottom” by producing in countries that are cheap to manufacture in. "In a 2017 McKinsey survey, 62% of chief purchasing officers at US and EU apparel companies said they were planning to diversify their sourcing away from China in the near to medium-term future. Bangladesh, Ethiopia, Myanmar, and Vietnam emerged as the top countries where respondents expect to increase sourcing." (Source: Bédat, 2021)

The fashion industry has known about these systemic issues for years, but little to nothing is happening to guarantee a living wage. The 2020 Fashion Transparency Index found that only 5 of the 250 large brands surveyed (2%) “publish a time-bound, measurable roadmap or strategy for how they will achieve a living wage for all workers across their supply chains,” and COVID-19 exposed another hard truth–since the start of the pandemic, brands grew 11% while decreasing workers’ wages by 21% (Source: Worker Rights Consortium, 2020). Of workers terminated during the pandemic, 70% did not receive their legally mandated severance pay (Source: Worker Rights Consortium, 2020).

We’ll conclude on a brighter note though. There is some progress being made. Legislation that restricts piece rate wages recently passed in the state of California, which guarantees all garment workers receive legal minimum wage, which is a significant increase compared to what they were receiving previously based on the number of units they could produce. Living wages are also being calculated at a faster rate globally by organizations like the Global Living Wage Coalition. With this data, the gap between actual wages and the living wage is made known to brands and suppliers, and will help lead to increased wages across the industry.

What we’re assessing on our Label

Data collection process & how we’re performing

We visit all of our Tier 1 suppliers regularly and review workers’ wages with each supplier’s HR team. We conduct frequent in-depth reviews with every supplier covering the following questions:

- What is the legal minimum wage in [insert country of operations]? Note that we also track this independently.

- What is your lowest worker’s wage?

- What are legally required overtime working rates? Are you complying with these rates?

- How are workers paid? Do they have a fixed salary, or are they paid by piece?

- At what frequency do workers get paid?

- How do you facilitate payment?

- Does a 3rd party verify wages?

- Do you have recurring 3rd party certification of the percentage of workers paid a family living wage? From whom?

We monitor individual living wages through 3rd party wage research from Wage Indicator and Trading Economics, and family living wages through benchmarks provided by the Global Living Wage Coalition in all of the countries we operate in. To ensure that 100% of our workers receive an individual living wage, we track suppliers’ lowest wages. If the lowest wage is at or above the living wage, everyone in that factory is receiving a salary deemed sufficient by these organizations to cover their basic needs.

While wages are self-reported from our suppliers in Mexico and Kenya, the factory we own and operate in Peru has undergone an in-depth 3rd party audit from Accountable (see findings here) that verified its wages are individual living wages. Today, 100% of workers at our Tier 1 suppliers receive an individual living wage, but no supplier is providing a family living wage to the majority of its workers. It’s on our roadmap to work with suppliers to provide 100% family living wages in the future. To learn more about our wages, read this post.

Health & Safety

State of the fashion industry

The fashion industry is responsible for the worst industrial accident in the history of the world to date.

The Rana Plaza factory collapse in 2013 killed 1,134 garment workers in Bangladesh. More than eight years later, Fashion continues to be a deadly business. High demand, short lead times, and razor-thin margins produce unsafe working environments where high production is prioritized while adherence to maintaining building integrity and fire code is neglected. Workers are still dying in regular factory fires and accidents at the cost of fast fashion–66 factory fires occurred in March 2020 alone in the industry’s global supply chain, an average of more than two per day. The fires resulted in four deaths and 50 injuries, and were reported in 18 countries with India–which accounted for 30% of the total–the worst affected (Source: GoBlu, 2020).

Although the industry is still far away from healthy and safe work environments being the norm, the resigning of The Bangladesh Accord on Fire and Building Safety from several large brands demonstrated legitimate signs of progress. Since 2013, the Accord’s independent factory inspections identified over 144,000 fire, electrical, and structural hazards across 1,600 garment factories in Bangladesh, more than 90% of which were remediated. Over 1.7 million workers were trained on workplace safety and 359 safety and rights complaints were resolved. The expansion of the Accord into other countries should lead to similar progress.

What we’re assessing on our Label

Data collection process & how we’re performing

We visit all of our Tier 1 suppliers regularly, and collaborate with HR teams to ensure they are providing a healthy and safe working environment. We conduct frequent in-depth reviews with every supplier covering the following questions:

- How do you manage health & safety in the factory?

- Do you have a health & safety system implemented to evaluate and eliminate hazards? Share about it in detail.

- How is the structural integrity and safety of the building evaluated? By whom and at what frequency?

- How have you structured your exit plan?

- What systems are in place in the case of an emergency?

- With what frequency do you check fire extinguishers?

- What personal protective equipment (PPE) are workers provided with?

- How do you train your workers on health & safety? At what frequency are workers trained?

- Who manages health & safety? What are their responsibilities?

- Do you have a health & safety team composed of management and workers? Do they meet regularly?

- Do workers have access to clean facilities, drinking water, and a clean space for breaks where they can eat?

- Have you had a 3rd party health & safety audit in the past? Do you have reoccuring health & safety audits? If yes, at what frequency?

- What were the findings from previous audits? What corrective actions have you taken?

- Has the factory obtained 3rd party certification for health & safety? From whom?

From these assessments, we’ve learned that all of our suppliers have established health & safety systems, policies, responsible team members, and 3rd party verification in place to cultivate a safe and healthy workplace. All of our suppliers have completed an independent health & safety audit, and several have reoccuring audits. Every worker is trained regularly on occupational emergency preparedness, and each supplier has a Health & Safety team that meets regularly to improve the work environment. We plan to more rigorously audit our suppliers through 3rd party organizations in the future.

Worker’s Rights & Governance

State of the fashion industry

“Despite hundreds of international standards, laws and regulations, and auditing and certification systems that exist to protect human rights and ensure decent working conditions, exploitation remains rife within the global fashion industry. Human rights abuses include cross-cutting issues such as excessively long working hours, repression of trade union organising, extremely low pay, lack of job security, gender and race-based discrimination and violence, unsafe and dangerous working conditions, and little to no access to justice for those whose basic rights are violated at work. These problems exist not just in places like Bangladesh, Cambodia and Mexico but also in the United States, United Kingdom and other parts of Europe.” (Source: Fashion Revolution, 2020)

Even though significant progress is being made to reduce child labor globally–a 47% decrease has occurred since 2000 largely due to consumer awareness (Source: ILO & UNICEF, 2020)–it is still prevalent across the fashion industry. There are an estimated 152 million children between the ages of 5-17 years in child labor, half of whom are in hazardous work including Fashion’s supply chain (Source: ILO, 2017). 51 countries use child labor in at least one part of their garment or jewellery supply chains and half a million children work producing cotton seeds (Source: Common Objective, 2018). Forced labor continues to be a major issue as well. The Walk Free Foundation (2018) produced a study based on data from 167 countries and interviews with 71,000 people in 52 languages and found that Fashion is one of the key industries contributing to modern slavery. According to Global Slavery Index, “clothing is at risk for directing the second-highest amount of money toward modern slavery, after tech.” (Source: Bédat, 2021)

It’s no surprise then that many factories foster abusive and unsafe working environments. An average garment worker’s day could be 14.6 hours in China or 17.4 hours in Bangladesh (Source: ILO, 2014). Countries regulate working hours differently, but most allow for long working hours and low minimum wages to bring in foreign investment from fashion brands. While all workers should be allowed to form and/or join a union to ensure their rights are provided to them, many around the world face challenges to actually make this a reality. Tension between labor rights activists and employers and government officials have resulted in violence in Cambodia, Bangladesh, Sri Lanka, and much of Southeast Asia (Source: The True Cost, 2015).

While the industry is taking some proactive action towards improving workers’ rights, much more is needed to be done in order to elevate workers’ voices and ensure an equitable future.

What we’re assessing on our Label

Data collection process & how we’re performing

We visit all of our Tier 1 suppliers regularly, and collaborate with HR teams to ensure they are elevating worker’s rights through maintaining ethical governance. We conduct frequent in-depth reviews with every supplier covering the following questions:

- What are your standard working hours? Do they ever exceed 60 hours per week?

- What breaks do workers receive during the workday?

- What time off do you provide during the week?

- How do you manage overtime hours? Are they voluntary and requested ahead of time? With what frequency do you request overtime? Do overtime hours ever exceed 12 hours a week?

- Does the factory have an active union?

- Do workers have the right to form and join a union? How are you making your workers aware of this right?

- How do you educate workers about their rights? Where and how do you disclose workers’ rights?

- Do you have a system and policies in place to eliminate and prevent discrimination, harassment, and abuse? Share about it in detail.

- Do you have a system and policies in place for workers to report grievances? Share about it in detail.

- How do you discipline workers if a situation arises that requires disciplinary action?

- Do workers have the right to leave their place of work without asking their supervisor?

- What does the career path look like for workers in your factory? Do they have the opportunity to get promoted and receive an increase in salary?

- Do you have an antidiscrimination plan and training in place? Share about it in detail.

- Does a 3rd party verify practices related to governance & workers’ rights?

- Do you have 3rd party certification for governance & workers' rights? From whom?

From these assessments, we’ve learned that all of our suppliers have established systems, policies, responsible team members, and 3rd party verification in place to ensure worker’s rights are met. While only one of our suppliers has an active union, all suppliers allow for freedom of association and bargaining. Additionally, the majority of our suppliers have established career paths in place for workers to move their way up in the factory. To learn more about our suppliers’ practices, read this post.

Gender Equality & Empowerment

State of the fashion industry

The fashion industry has the potential to eradicate poverty for tens of millions of women around the world, in addition to their dependents. Instead, 95%+ are held in systemic poverty, oftentimes in unsafe and abusive work environments–an estimated 68% of fast fashion brands don’t maintain gender equality at production facilities (Source: Ethical Fashion Guide, 2019), which naturally leads to abuse since men tend to work in supervisory and management positions.

“Sexual harassment and gender-based violence are common in the fashion supply chain. One in every two women workers in garment factories in Southeast Asia has experienced sexual harassment, according to on-the-ground reports from CARE International (2019). Further recent research from Solidarity Center (2019a) has documented sexual harassment and violence against women workers in Cambodia and Indonesia, which has included unwanted touching, verbal insults, rape and abuse of pregnant workers.” (Fashion Revolution, 2020)

The industry is far from where it needs to be when it comes to assessing and improving its impact on women and their family members. While it could function as a platform for helping women achieve their aspirations, it tends to trap them in poverty and create further trauma.

What we’re assessing on our Label

Data collection process & how we’re performing

We visit all of our Tier 1 suppliers regularly, and collaborate with HR teams to ensure they are empowering workers who identify as women. We conduct frequent in-depth reviews with every supplier covering the following questions:

- How do you evaluate health & safety risks for individuals identifying as women?

- Have you ever forced a worker to take a pregnancy or virginity test?

- Do you have a system and policies in place to eliminate and prevent gender-based discrimination, harassment, and abuse? Share about it in detail.

- Have individuals who identify as women expressed that they feel safe from harassment and abuse?

- Are individuals identifying as women paid the same as men for the same position, level of experience and performance?

- Is there equal opportunity for promotion regardless of gender?

- What is your maternity leave policy?

- What percentage of your leadership team is composed of individuals identifying as women?

- Do you have programming in place to empower individuals who identify as women? Share about it in detail.

- Do you provide additional support for single mothers?

- Do you provide opportunities for continued education for individuals who identify as women?

- Do you proactively employ individuals identifying as women to roles in which women are underrepresented?

- Is the factory owned by at least one person identifying as female?

- Does a 3rd party verify practices related to gender equality & empowerment?

- Do you have 3rd party certification or a completed audit for gender equality & empowerment? From whom?

From these assessments, we’ve learned that all of our suppliers have established systems and policies in place to empower individuals who identify as women, in addition to female representation at the leadership level. Several suppliers have programming for continued education and professional development, and one of our suppliers proactively employs women in positions typically occupied by men. To learn more about our suppliers’ practices, read this post.

Healthcare & Benefits

State of the fashion industry

Little research has been done to evaluate whether workers in the industry are receiving healthcare and benefits. Considering that fast fashion relies on cheap labor in emerging markets that have little to no regulations, it can be confidently assumed that most workers do not receive sufficient healthcare and benefits. Additionally, a large share of the world’s clothes are made in the informal economic sector where compliance to legal minimum wages and benefits does not occur.

What we’re assessing on our Label

Data collection process & how we’re performing

The provision of healthcare and benefits is often overlooked by industry assessments and standards, but it’s actually one of the best methods to positively impact workers and their families. That’s why we visit all of our Tier 1 suppliers regularly and collaborate with HR teams to ensure they are providing healthcare and benefits to all of their workers. We conduct frequent in-depth reviews with every supplier covering the following questions:

- What are the legally required benefits to provide in [insert country of operations]? Note that we also track this independently.

- Do you comply with these benefits?

- What supplementary benefits do you provide? Share about them in detail.

- How much paid time off do you offer?

- Do you provide bonuses or other compensation benefits? Share about them in detail.

- Do you provide healthcare to workers and their family members? What percentage of the healthcare plan do you cover?

- Do you provide professional development training to support workers’ advancement in the factory?

- Do you provide medical, physical, emotional, and mental health trainings? At what frequency?

- Do you provide personal finance programming? Do you offer savings groups?

- Do you provide opportunities for continued education?

- Are benefits that extend to family members provided?

- Do you have a profit sharing program in place?

- Do you have an established Relief Fund to ensure workers can continue to meet basic needs through emergencies like natural disasters and global events (e.g., COVID-19)?

- Do you provide a Fair Trade Premium?

- Do you offer daycare for workers’ children?

- Does a 3rd party verify the provision of healthcare and benefits?

- Do you have 3rd party certification for healthcare and benefits? From whom?

From these assessments, we’ve learned that all of our suppliers are providing healthcare and complying with legally required benefits, in addition to providing supplementary benefits. Several suppliers have programming for improving workers’ medical, physical, emotional, and mental health, in addition to personal finance training and savings groups. In Peru, we established a Relief Fund in the wake of COVID-19 to ensure our workers’ basic needs were met. To learn more about our suppliers’ practices, read this post.

Social components are only half of what should be assessed on a Label. Caring for people AND the planet are not mutually exclusive. They can, should, and MUST happen simultaneously.

Planet

We envision the fashion industry regenerating the natural environment instead of depleting it. We believe Fashion can reverse its impact on climate change, and inspire other industries to do their part in saving the planet. In contrast to fast fashion’s “take, make, dispose” model, we believe in a “circular fashion” approach that takes environmental impact into account at all stages ranging from initial design, to the sourcing of materials, to manufacturing, to logistics to the final customer, to the end lifecycle of products post consumer use, and all steps in between. We embrace a circular and holistic approach to environmental impact by focusing on the following five areas: carbon footprint, raw materials integrity and durability, processing and manufacturing, packaging and distribution, and post use product lifecycle.

Carbon Footprint

State of the fashion industry

Creating 1.2 billion tons of annual greenhouse gas emissions and on pace to account for 26% of emissions by 2050, the fashion industry is one of the worst contributors to climate change, emitting more emissions than the international aviation and maritime shipping industries combined (Source: Ellen MacArthur Foundation, 2017). Brands are starting to monitor their carbon emissions due to pressure from consumers and other advocate groups. Still though, a significant amount of the industry has taken no action, which is concerning in light of the most recent report from the Intergovernmental Panel on Climate Change making the scientific case that we need to decarbonize entire industries more rapidly if we are going to meet the 1.5 degree global warming threshold.

A growing number of brands are taking more extreme action by measuring, reducing, and offsetting 100% of their carbon emissions through Climate Neutral Certification. The industry at large should continue to adopt this practice and innovate in order to decarbonize as quickly as possible.

What we’re assessing on our Label

Data collection process & how we’re performing

As we mentioned earlier in this post, we measure and offset 100% of our Scopes 1, 2, and 3 CO2 emissions as a Certified Climate Neutral brand. Climate Neutral ensures that we are accurately measuring and offsetting 100% of these emissions by requiring us to measure our emissions on their software tool, the Brand Emissions Estimator (BEE), a comprehensive platform built in partnership with climate experts from well respected organizations–Massachusetts Institute of Technology and CIRAIG, among others–operating in the carbon emissions accounting and lifecycle analysis fields (see their complete methodology here). To certify, we share financial information and specific emissions data (e.g., total ton miles shipped, kilowatts of energy consumed, therms of natural gas used, amount of leather hides purchased, etc.) into the BEE to arrive at an accurate estimate of our total carbon emissions. An analyst from Climate Neutral works directly with our Sustainability Lead to ensure there are no discrepancies in the data, supports us with creating and implementing reduction plans to actually reduce our carbon footprint moving forward, and verifies that 100% of our CO2 emissions are offset annually through a REDD+ project in the Peruvian Amazon that has been certified through the Verified Carbon Standard (VCS). You can learn more about the conservation work we support here.

Raw Materials Integrity & Durability

State of the fashion industry

Did you know that most of our clothes are made from oil and plastic? 63% of textile fibers are derived from petrochemicals that take centuries to degrade in landfills (Source: Journal of Cleaner Production, 2018). “Nearly 70 million barrels of oil are used each year to make the world’s polyester fiber, which is now the most commonly used fiber in our clothing. But it takes more than 200 years to decompose.” (Forbes, 2015) These low quality materials make our clothes less durable and more disposable. “One in three young women, the biggest segment of consumers, consider garments worn once or twice to be old” (Source: The Guardian, 2019), and three out of five fast fashion items end up in a landfill (Source: Clean Clothes Campaign, 2019).

The fashion industry is operating under a “take, make, and dispose” model that’s having a detrimental and oftentimes irreversible impact. A significant amount of the raw materials that make up our clothing originate from our natural environment, and the fashion industry is responsible for changing the physical landscape of our planet for the worse. Fashion is projected to use 35% more land for fiber and textile production by 2030—an extra 115 million hectares that could be left to preserve biodiversity (Source: Global Fashion Agenda, 2017). “Forests are felled to make way for cotton farming, cattle grazing that supplies leather, and to create wood-based fabrics...Forests are not only vital for biodiversity but they also act as a carbon sink, capturing carbon dioxide that would otherwise be in our atmosphere. And, when forests are cleared or burnt, they release carbon emissions. The industry needs to move towards regenerative agriculture and production processes to ensure that our living planet remains fit for survival.” (Source: Fashion Revolution, 2020)

A growing number of brands are beginning to leverage recycled materials and innovative technologies to make new products that have a much smaller environmental impact, but the industry is still far away from adopting these forward thinking practices at a larger scale.

What we’re assessing on our Label

Data collection process & how we’re performing

We build quality products made with durable raw materials. 100% of our leather is cow leather and a byproduct of the meat industry. Defined as “an incidental or secondary product made in the manufacture or synthesis of something else,” we can be certain that leather is a byproduct because a cow hide is only 2.29% of the economic value of the entire animal (Source: United States Department of Agriculture, 2020). No cow would ever be killed for the exclusive purpose of creating leather. By using the hide, we play a role in diverting it from immediately ending up in a landfill. If these hides were not repurposed into leather, we would have a huge waste issue on our hands. An estimated 33 Million hides would go into landfills annually in the US alone (Source: Leather Hide Council of America, 2019). It’s also incredibly durable, repairable, recyclable for new products, and not as care intensive as apparel. We do not use any oil-based materials or synthetics like polyester in our primary raw materials and are committed to never using plastic or fossil fuel based materials unless they are 100% recycled and recyclable at the end of their life.

We are committed to further evaluating our farms’ animal welfare policies and practices and will use our influence to support best animal husbandry practices. We have a strict commitment to never use exotic skins (e.g., ostrich, crocodile, kangaroo, elephant, lizard, snake, etc.), or fur for our products due to the historic animal rights abuses of these industries. We are committed to ensuring the wellbeing of the cattle within our supply chain, and we are committed to ensuring the Five Freedoms are met within our supply chain: freedom to express natural behavior, freedom from injury and disease, freedom from discomfort, freedom from thirst and hunger, and freedom from fear and distress.

We are working in collaboration with our tanneries to map 100% of our leathers back to the farm level. As of 2021, whereas we still have a long way to go on this front, we can map approximately 25% of our leathers back to the exact farm of origin. We do know that 100% of our leather is cow leather and a byproduct of the meat industry, and our suppliers have guaranteed that no deforestation is occurring within our supply chain. While we are still learning more about the base of our supply chain in our pursuit to obtain a comprehensive list of Tier 4 suppliers, we know that our leather comes from Mexico and the United States (primarily Kansas & Nebraska), so it does not contribute to deforestation in the Amazon. Read more about our holistic approach to working with leather here.

Most of our brass jewelry line comes from fully recycled materials, which our artisans upcycle into finished products.

Processing & Manufacturing

State of the fashion industry

The fashion industry relies heavily on natural resources and hazardous chemicals to manufacture its products.

“Freshwater is a highly limited commodity and its supply is diminishing. A full two thirds of the world’s population are projected to face water scarcity by 2025, according to the UN. This is not because water molecules are disappearing; it’s because existing freshwater is getting polluted, rendering it unsafe for human consumption, and the chemicals from our clothing contribute to this water crisis.” (Source: Bédat, 2021) As much as 20% of industrial water pollution comes from washing, solvents, and dyes (Source: Mckinsey, 2020), and if the water and chemical waste from making our clothes isn’t treated, it will run off into natural waterways and create serious health problems for nearby communities and the planet at large (Source: The True Cost, 2015). Microplastics from our clothing are winding up in rivers and oceans that pollute marine ecosystems at alarming rates–Fashion accounts for 20 to 35 percent of microplastic flows into the ocean (Source: Mckinsey, 2020).

Even if factories comply with local legislation for managing chemicals, water usage, and energy, Fashion is still largely unregulated, especially in the deeper tiers of the supply chain.

It is possible to manufacture clothes and shoes with natural methods and materials that are not resource intensive–regenerative methods are even possible–but the industry at large is far from making this more sustainable model a reality. Most brands do not have visibility beyond their Tier 1 suppliers and take little to no responsibility for the rest of their supply chain.

What we’re assessing on our Label

Data collection process & how we’re performing

We have complete visibility of Tiers 1 and 2 across all of our products’ primary raw materials, and are beginning to achieve visibility of Tiers 3 and 4. Over the past 18 months, we have invested hundreds of thousands of dollars to completely rework Tier 2 of our supply chain in order to source from Leather Working Group (LWG) Certified tanneries that prioritize environmental responsibility. The majority of our leather comes from LWG Certified tanneries, which means they have been evaluated and certified for best practices against the following criteria: material traceability, environmental management system, restricted substances, energy consumption, water usage, air and noise emissions, waste management, effluent treatment, health, safety, and emergency preparedness, chemical management, and operations management. 100% of our leathers will be LWG Certified within the next two years.

Providing LWG Certified tanneries with our preferred supplier status has had a significant positive impact in the following areas:

- Carbon emissions – LWG Certified tanneries monitor air emissions, as this is a critical part of LWG’s protocol. Tanneries detail all points of forced emissions to air (i.e. boiler stacks, spray machines, fume cupboards, etc.), in addition to the results of environmental aspects and impacts assessments made upon those emissions. In this way, we have invested in reducing the negative health impacts of pollution along our value chain.

- Water management and stewardship – LWG Certified tanneries must have operating permits in place depending on their geographical location when it comes to water consumption, usage, and discharge into local waterways. Tanneries undergo a re-audit every 2 years and are required, as part of the protocol, to provide water pollution data based on the previous months to show either an improved rating, or maintenance of a high standard of water quality, to enable them to remain LWG Certified.

- Chemical management – LWG Certified tanneries are required to manage and dispose of their chemicals responsibly, and are aligned with our commitment to avoid the use of hazardous chemicals.

Our shift towards working with LWG Certified tanneries and vegetable tanning has significantly reduced the chemical pollution that occurred in our supply chain when we sourced a much higher percentage of products from tanneries that did not have these 3rd party verified practices and systems in place, and this was a primary motivator for reshaping our supply chain and raw materials providers over the last few years.

We are working to enhance the level of auditing done both by internal and external parties to evaluate our supply chain. Any Tier 2 supplier that did not have LWG Certified status was audited by our Sustainability Lead. These suppliers confirmed they are complying with applicable laws and have developed their environmental management systems and practices using industry-leading practices and standards.

Packaging & Distribution

State of the fashion industry

Packaging for our clothes and shoes is typically composed of single-use plastics and materials that immediately wind up in landfills, and shipping emissions contribute significantly to Fashion’s carbon footprint. “The fashion industry has long been dependent on plastic for wrapping, hanging, tagging and shipping, although of course the plastic packaging problem is not exclusive to fashion. In just the U.S. alone, 380 billion plastic bags and wraps are used each year, according to the Environmental Protection Agency (EPA). Many of these single-use plastics are not recycled or disposed of properly.” (Source: Triple Pundit, 2021)

Much of the fashion industry is transitioning towards more environmentally responsible packaging, but the volume of packaging and high concentration of plastic is still concerning. This is the least costly option for a brand and manufacturer to enhance its image to consumers, which is why we are seeing progress here in the industry.

Thankfully, recycled cardboard is a more environmentally friendly option for packaging and also happens to be one of the cheaper options as well, thus leading to its growing adoption.

What we’re assessing on our Label

Data collection process & how we’re performing

We are committed to improving packaging materials and recyclability and reducing shipping emissions. We measure and offset 100% of our upstream (factory to distribution center) and downstream (distribution center to customer) shipping, and have achieved reductions in shipping emissions by relying more heavily on ocean shipments vs. air. The majority of our packaging is made from recycled corrugated cardboard and is fully recyclable. We are in the process of overhauling our packaging to make it even more environmentally responsible, and from SS22 forward, we plan to utilize a single box instead of double boxing our products, which will cut our packaging materials and impacts in half when we compare 2021 to 2022.

Post Use Product Lifecycle

State of the fashion industry

With the rise of fast fashion in the 1990s, our clothes became cheaper and more disposable than ever before. American shoppers are buying five times more now than they did in 1980, which averages out to 68 garments per year (Source: Rent The Runway, 2018). Each piece is only worn a handful of times before it gets tossed; estimates range from three to seven wears, on average. This increased consumption correlates with increased fashion waste–between 1999 to 2009 post consumer textile waste grew by 40% (Source: Environmental Protection Agency, 2009). Rubber, leather, and textiles make up more than 9% of municipal solid waste in the United States, and the average American throws out 81 pounds of clothing every year (Source: Environmental Protection Agency, 2016). The worst part is that 95% of our clothing and shoes can be recycled or reused, yet 85% ends up in landfills and can take decades (sometimes even centuries) to biodegrade (Source: Council for Textile Recycling, 2021).

When our clothes do reach the landfill, they continue to emit greenhouse gases, and waste from the Global North typically ends up in landfills polluting the Global South since only 10-20% of what second hand retailers collect can be resold in the Global North (Source: The OR Foundation). The United States exports more than a billion pounds of clothing every year (Source: NPR, 2013) and “more than half of our clothing that is sent to Accra [Ghana, one of the largest recipients of secondhand clothing globally] goes to the landfill.” (Source: Bédat, 2021) We keep our waste out of sight out of mind by making it someone else’s problem, and that “someone else” is almost always in the Global South. “Wearing a garment twice as long would lower greenhouse gas emissions from clothing by 44 percent” (Source: Bédat, 2021).

The fashion industry has traditionally done a poor job of circulating used products back into the supply chain to create new ones. “Less than 11% of brands are implementing recycling strategies for their items” (Peppermint Magazine, 2019) and “More than $500 billion of value is lost every year due to clothing underutilization and the lack of recycling” (Ellen MacArthur Foundation, 2017). That said, the industry is starting to recognize the scale of its waste and take action towards remediating it.

What we’re assessing on our Label

Data collection process & how we’re performing

Our intention is to keep our products in use as long as possible, which is why we aggressively push the sales of our leather cleaning kits and products that better care for our goods, in addition to educating our customers on how to maintain our products. At the end of the product life, we encourage customers to recycle and dispose of their products responsibly when necessary. We offer leather care kits and upcycling services at 100% of our brick-and-mortar locations, and we incentivize customers to use these services by offering free shipping when they want to mail products in as well as $40-50 credit on future purposes when they recycle their footwear as part of our product reclamation program in partnership with Soles4Souls.

As we continue to combat the excessive amount of landfill waste that fast fashion has created, we are committed to working under a circular fashion model—a system that reuses and recirculates products and materials. Since launching this program, we have collected and diverted 7,052 pairs of used shoes from landfills, which averages to approximately 2,350 pairs per year. 100% of these shoes have been donated to Soles4Souls, a Nashville based organization that distributes donated items to various programs around the world to help individuals and communities in need.

Soles4Souls’ programs are distinct from typical distribution schemes that wind up polluting the Global South, and 0% of donated products go straight to landfills or incinerators. S4S is “helping hard-working entrepreneurs build their own businesses selling donated new and used shoes and clothing to step out of poverty.” Moreover, through S4S, small business owners earn a sustainable living wage and are able to purchase necessities like food, shelter, and education for their families. S4S develops sustainable partnerships and programs in which shoes and clothing are a vehicle for equitable, educational, and economic opportunities. And in turn, they empower people to break the cycle of poverty. S4S works alongside partners to unlock economic opportunities for people to maximize their potential and provide access and representation for all people, especially more vulnerable communities such as women, youth, and people of color.”

We know that was a lot of information to digest. That’s why we present it in a much more consolidated format on our actual product labels. If you’ve made it this far, thank you for your interest in learning the ins and outs of our methodology. Let’s jump out of the weeds and conclude with what we hope for in the future, and next steps for improvement.

As we mentioned at the beginning of this post, this scoring methodology is not perfect. We intend for this to be a starting point that experts and academics can build on together. The fashion industry desperately needs a consumer-facing label that communicates sustainability holistically in a manner that is digestible. That said, we encourage radical collaboration to build out this tool even further.

We plan to extend our people ratings to be inclusive of the rest of the supply chain and commit more resources to auditing our entire supply chain. Ideally, every claim we make should have 3rd party verification and certification backing it. Even though we’re a ways away from that, we are confident we can get there, and we’ve learned a lot of valuable information about our supply chain through this self assessment.

We want to hear from you!

Our label is far from perfect, and we’d love your feedback on how you think we can enhance this label and how we can better operate as a brand.

Please send us an email at label@nisolo.com to share what you’d like to see on our label and methodology or any other feedback you might have for us.

Acknowledgments

First and foremost, we want to thank the workers within our supply chain. None of this would be possible without you, and we are humbled to have worked alongside you now for over a decade. We’re in business because of you and for you, and you’ve had a greater impact on us than we could ever have on you. Thank you for sharing your time and wisdom with us. You make us better.

Thank you to Yvon Chouinard and others who have envisioned a consumer-facing label that communicates a product’s social and environmental impacts for a long time now. A nutrition label for the fashion industry is not a new concept. Labels that communicate a product’s social and environmental impacts have been, and are becoming, more prevalent. In order for us to build one of the most comprehensive, digestible labels to ever be brought to market, we benefited from the library of great work that’s already been done.

On that note, we want to express our gratitude for the work of the following organizations, tools, and bodies of academic work that played a role in informing this label and methodology for the industry.

Bibliography of Certifications, Assessments, Labels, & Organizations

-

Sustainable Apparel Coalition’s Higg Index.

https://apparelcoalition.org/the-higg-index/ -

Better Work Programme resources from the International Labour Organization and International Finance Corporation.

https://betterwork.org -

Social Accountability International’s SA8000 Standard.

https://sa-intl.org/programs/sa8000/ -

Fair Labor Association’s Workplace Code of Conduct and Compliance Benchmarks.

https://www.fairlabor.org/ -

Fair Trade USA’s Factory Standard for Apparel and Home Goods.

https://www.fairtradecertified.org/ -

B Lab’s B Impact Assessment.

https://bcorporation.net/about-b-lab -

Global Living Wage Coalition’s Family Living Wage Methodology and Benchmarks.

https://www.globallivingwage.org/ -

Wage Indicator and Trading Economics’ Individual Living Wage Methodologies and Benchmarks.

https://wageindicator.org/Wageindicatorfoundation -

Eco-Age’s Sustainability Benchmark.

https://eco-age.com/agency/principles/ -

Accountable’s Factory Auditing Assessment.

https://www.lowestwagechallenge.com/ -

Textile Exchange’s Organic Content Standard.

https://textileexchange.org/ -

Cradle to Cradle’s Product Standard.

https://www.c2ccertified.org/ -

Climate Neutral’s Standards.

https://www.climateneutral.org/ -

Doconomy’s 2030 Calculator for CO2 Emissions.

https://doconomy.com/ -

Eon’s Digital ID.

https://www.eongroup.co/circular-product-data-protocol -

Accenture’s Impact Index.

https://www.accenture.com/us-en/insights/retail/impact-index-fashion -

Leather Working Group’s Audit Protocols.

https://www.leatherworkinggroup.com/?gclid=Cj0KCQiAnuGNBhCPARIsACbnLzpKenmjDBliummcfY3UI6Fkm52SLioUsAqRkXe7hiokHznw63ywcXcaAgu5EALw_wcB -

Framework for Regenerative Organic Certified Products.

https://regenorganic.org/ -

ZQ’s Grower Standard Manual.

https://www.discoverzq.com/ -

Savory Institute’s Land to Market Program.

https://savory.global/land-to-market/ -

Oeko-Tex’s Standard 100.

https://www.oeko-tex.com/en/ -

bluesign’s CRITERIA for production sites.

https://www.bluesign.com/en/business/the-blue-way -

REACH Criteria and Guidelines.

https://echa.europa.eu/regulations/reach/understanding-reach -

Re/Make’s Fashion Accountability Report Methodology.

https://remake.world/2021-remake-fashion-accountability-report/ -

Good On You’s Ratings Guide.

https://goodonyou.eco/how-we-rate/ -

Fashion Revolution’s Fashion Transparency Index Methodology.

https://www.fashionrevolution.org/about/transparency/ -

Asket’s Impact Receipt.

https://www.asket.com/us/transparency/impact -

Allbirds’ Carbon Footprint Label.

https://www.allbirds.com/pages/footprint -

Cocokinds’ Sustainability Facts Label.

https://www.cocokind.com/pages/transparency-evolved -

Pantys’ Carbon Footprint Label.

https://pantys.com/pages/carbon-neutral - Invisible Bag’s Packaging Label.

https://www.invisible-company.com/pages/invisiblebag

Bibliography of Supporting Research

- “2017 Pulse Of The Fashion Industry,” Global Fashion Agenda and Boston Consulting Group, https://www.globalfashionagenda.com/publications-and-policy/pulse-of-the-industry/, 2017.

- “2019 Ethical Fashion Report,” Peppermint Magazine, https://peppermintmag.com/2019-ethical-fashion-report/, 2019.

- “2020 Fashion Transparency Index,” Fashion Revolution, https://issuu.com/fashionrevolution/docs/fr_fashiontransparencyindex2020?fr=sNmI5NzYxMDk0OA, 2020.

- “A New Textiles Economy: Redesigning Fashion’s Future,” Ellen Macarthur Foundation, https://ellenmacarthurfoundation.org/a-new-textiles-economy, 2017.

- “Advancing Sustainable Materials Management: 2014 Fact Sheet,” Environmental Protection Agency, https://www.epa.gov/sites/default/files/2016-11/documents/2014_smmfactsheet_508.pdf, 2016.

- “AR6 Climate Change 2021: The Physical Science Basis,” Intergovernmental Panel on Climate Change, https://www.ipcc.ch/report/ar6/wg1/, 2021.

- “Are The People Who Made Your Clothes Paid Enough To Live On?” Fashion Checker by Clean Clothes Campaign, https://fashionchecker.org/, 2020.

- “Child Labour In The Fashion Industry,” Common Objective, https://www.commonobjective.co/article/child-labour-in-the-fashion-industry, 2018.

- “Confronting Plastic Pollution One Bag At A Time,” The EPA Blog, https://blog.epa.gov/2016/11/01/confronting-plastic-pollution-one-bag-at-a-time/, 2016.

- Council for Textile Recycling, https://www.weardonaterecycle.org/, 2021.

- “Covid-19 and Garment Workers,” Worker Rights Consortium, https://www.workersrights.org/issues/covid-19/, 2020.

- “Covid-19 May Push Millions More Children Into Child Labour,” ILO and UNICEF, https://www.unicef.org/press-releases/covid-19-may-push-millions-more-children-child-labour-ilo-and-unicef, 2020.

- “Environmental Impact Of Textile Reuse And Recycling,” Journal of Cleaner Production, https://www.sciencedirect.com/science/article/pii/S0959652618305985#bib39, 2018.

- “Fast Fashion Is On The Rampage, With The UK At The Head Of The Charge,” The Guardian, https://www.theguardian.com/fashion/2019/jun/21/fast-fashion-is-on-the-rampage-with-uk-at-the-head-of-the-charge, 2019.

- “Fires In The Fashion Industry Supply Chain,” GoBlu, https://www.goblu.net/in-the-news/2020/4/8/fires-in-the-fashion-industry-supply-chain-report-featured-on-ecotextile-news, 2020.

- “Gender-based Violence And Harassment At Work,” Solidarity Center, https://www.solidaritycenter.org/category/what-we-do/equality-inclusion/gender/, 2019.

- “Global Estimate of Child Labour: Results And Trends, 2012-2016,” ILO, https://www.ilo.org/global/publications/books/WCMS_575499/lang--en/index.html, 2017.

-

“Global Fashion Industry Statistics,” Fashion United,

www.fashionunited.com/global-fashionindustry-statisticsinternational-apparel, 2017. - “Making Climate Change Fashionable–The Garment Industry Takes On Global Warming,” Forbes, https://www.forbes.com/sites/jamesconca/2015/12/03/making-climate-change-fashionable-the-garment-industry-takes-on-global-warming/?sh=1880f8679e41, 2015.

- Maxine Bédat, Unraveled, 2021.

- “Modern Slavery: A Hidden, Every Day Problem,” Walk Free Global Slavery Index, https://www.globalslaveryindex.org/2018/findings/highlights/, 2018.

- “Money Fashion Power,” Fashion Revolution, https://www.fashionrevolution.org/resources/fanzine/, 2017.

- “Municipal Solid Waste In The United States 2009 Facts And Figures,” Environmental Protection Agency, https://archive.epa.gov/epawaste/nonhaz/municipal/web/pdf/msw2009-fs.pdf, 2009.

- “The Afterlife of American Clothes,” NPR, https://www.npr.org/sections/money/2013/12/10/247362140/the-afterlife-of-american-clothes, 2013.

- “The State of Fashion 2020,” Mckinsey & Company, https://www.mckinsey.com/~/media/mckinsey/industries/retail/our%20insights/the%20state%20of%20fashion%202020%20navigating%20uncertainty/the-state-of-fashion-2020-final.pdf, 2020.

- “Poverty Wages,” Clean Clothes Campaign, https://cleanclothes.org/poverty-wages, 2013.

- “Rent The Runway Wants To Lend You Your Look,” The New Yorker, https://www.newyorker.com/magazine/2018/10/22/rent-the-runway-wants-to-lend-you-your-look, 2018.

- “Sexual Harassment, Exploitation And Abuse Transparency Report,” CARE International, https://www.care-international.org/news/press-releases/care-international-sexual-harassment-exploitation-and-abuse-transparency-report-2019, 2019.

- “The 2019 Ethical Fashion Report: The Truth Behind The Barcode,” Ethical Fashion Guide, https://media.business-humanrights.org/media/documents/files/documents/FashionReport_2019_9-April-19-FINAL.pdf, 2019.

- The OR Foundation, https://theor.org/, 2021.

- The True Cost Film, Andrew Morgan, 2015.

- “Universal Declaration of Human Rights,” United Nations, https://www.un.org/en/about-us/universal-declaration-of-human-rights, 2021.

- US Department of Agriculture AMS Daily Drop Credit Report, https://www.youtube.com/watch?v=Rp7vls0LeXg&t=2855s, 3/23/2020.

- “Waste And Pollution,” Clean Clothes Campaign, https://cleanclothes.org/fashions-problems/waste-and-pollution, 2019.

- “World of Work Report 2014,” ILO, https://www.ilo.org/global/research/global-reports/world-of-work/2014/lang--en/index.htm, 2014.

- “Why We Still Need A Fashion Revolution,” Fashion Revolution, https://issuu.com/fashionrevolution/docs/fr_whitepaper_2020_digital_singlepages, 2020.